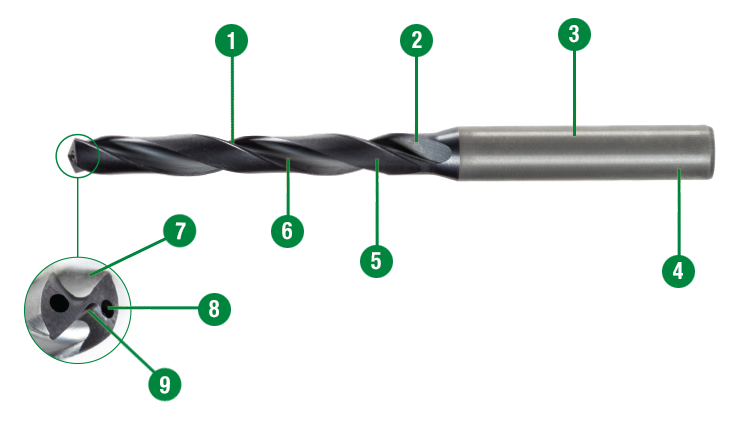

Top Drill S™ Stainless Steel

Productivity & Performance

- – Excellent chip flow due to flute design and finish.

- – New coating enables higher cutting speeds.

- – Higher feed rates on stainless steels and duplex.

- – Available for custom solutions, as well as step-drilling.

- – Real 8 x D drill lengths.

- – Cylindrical shank h6 for perfect runout.

- – Double-margin design for critical operations.

TDS45x for Stainless Steel

WM15PD Grade

A multilayer, AlTiN-based coating with high hot hardness enables high-speed drilling and MQL applications.

Patented TDS Point

Excellent centering. Highest feed and speeds. Force reduction.

- 2 margin lands

Provide stability in the cut and reduce friction. - Web and envelope taper

Free chip flow. - Fine-grained substrate

Reduces risk of fracture. - h6 Precision shank

- Round cylindrical.

- DIN. Low runout.

- Suitable for Shrink Fit chucks.

- Unique new polished surface

Reduction of friction in the chip flute and on the lands; drastically improved tool life. - Large chip-flute cross-section, small core diameter

Drastically improved chip evacuation; capability to drill deeper holes in difficult-to-machine materials. - Straight cutting edge

Long tool life and less chipping on cutting edge. - Coolant holes

Provide optimum coolant flow. - New gash design

Easy chip formation and flow.